Sapphire Mining

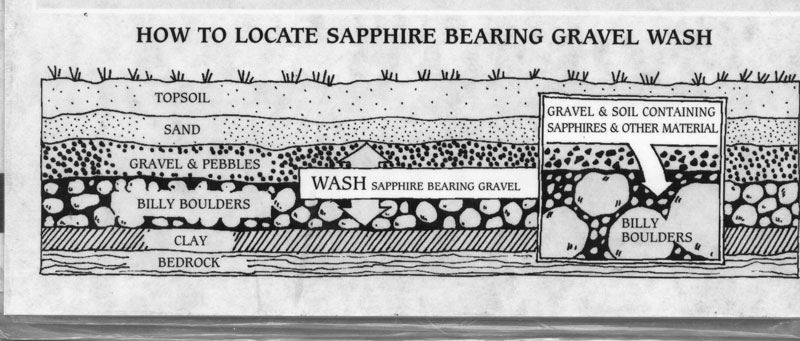

Peter mines in an area where the “wash” (which is the sapphire bearing dirt) is about 10 metres deep, so he starts by having a shaft drilled which is a 900mm diameter hole.

He sets his mining rig up over the shaft and attaches the ladders from the rig down the shaft.

The automatic hoist on the mining rig pulls the bucket up the ladder to carry the wash up to the surface and dumps it into the bin.

Peter can then start tunnelling around underground, first digging with a jackhammer, then when the area dug out is big enough he puts his big hydraulic breaker in which can break the dirt down off the walls of the tunnel.

He shovels up the dirt into a wheelbarrow and wheels it back to the shaft and dumps it into the bucket of the mining rig.

He pulls the hoist lever which sends the bucket up and thus begins the processing.

Washplant Process

Peter’s mining rig features:

- An Automatic Hoist to bring the sapphire bearing wash to the surface and dump it in the bin.

- The Bin with a grizzly over it to sieve large rocks out and feed the rest to the conveyor.

- The Conveyor which carries the wash to the trommel.

- The Trommel which sieves the sand out and feeds the rest of the wash to the pulsator.

- And The Pulsator which creates a wave action with the water which washes the rocks and because sapphires are heavier than all other rocks they get worked down to the bottom of the trays while all the other rocks get washed out of the trays.

All with 3 phase electric motors.

The Sapphires are then hand picked out of the pulsator trays after the washing process.